Tevo Tarantula Models Top 5 Features

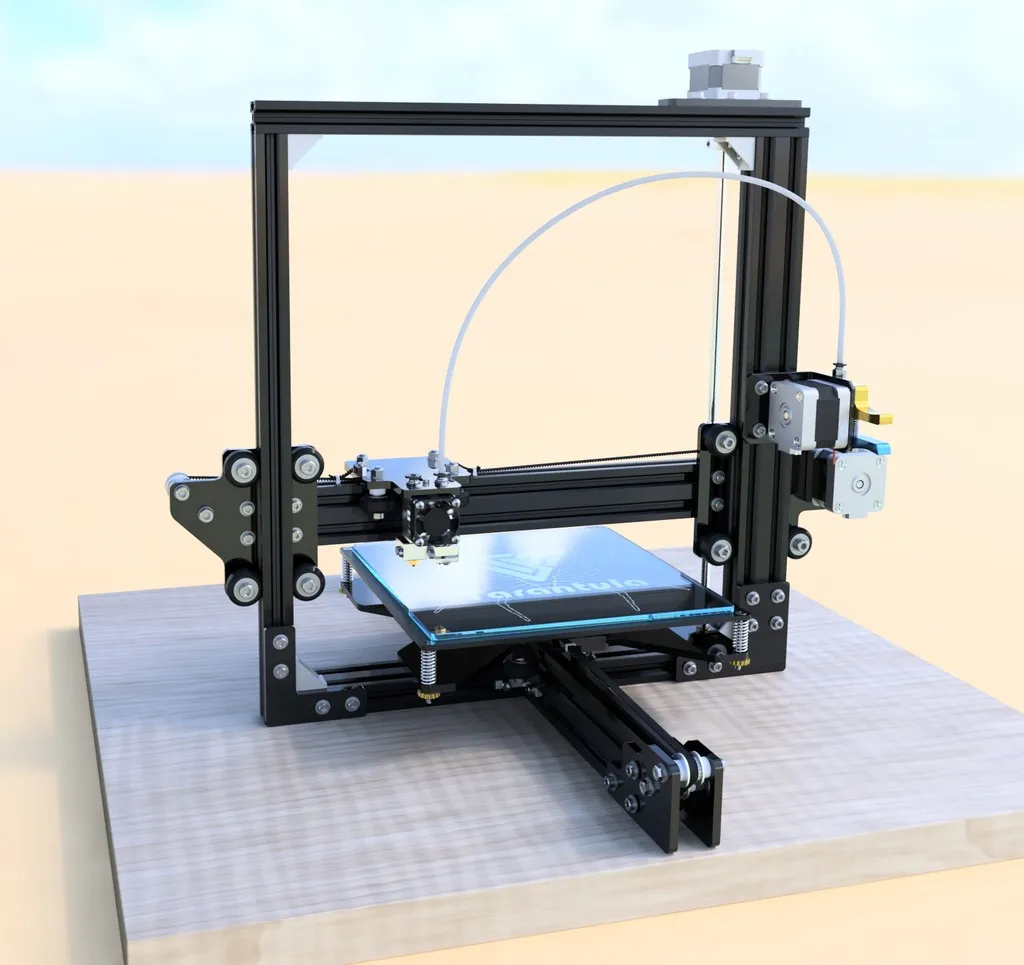

The Tevo Tarantula has gained a reputation as a budget-friendly 3D printer offering impressive features and capabilities. It’s popular among hobbyists and beginners due to its ease of use, affordability, and community support. While several models exist within the Tevo Tarantula lineup, certain features consistently stand out, making it a worthy contender in the ever-evolving 3D printing market. This article dives deep into the top 5 features that make Tevo Tarantula models a popular choice.

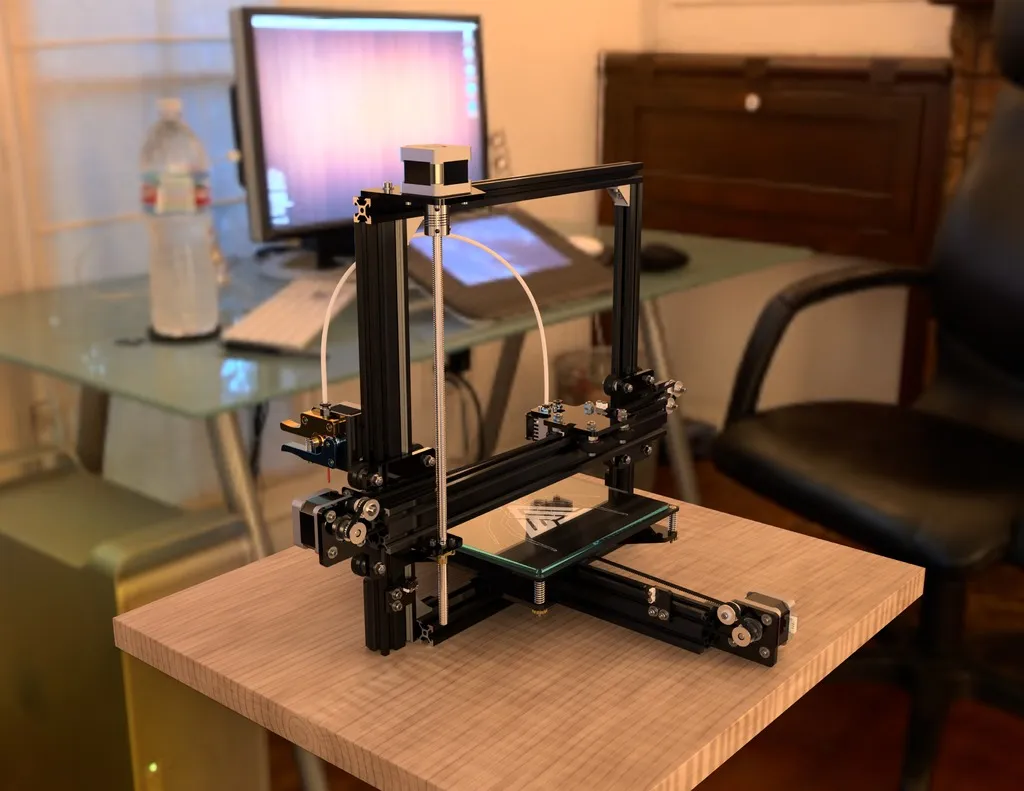

Design and Build Quality

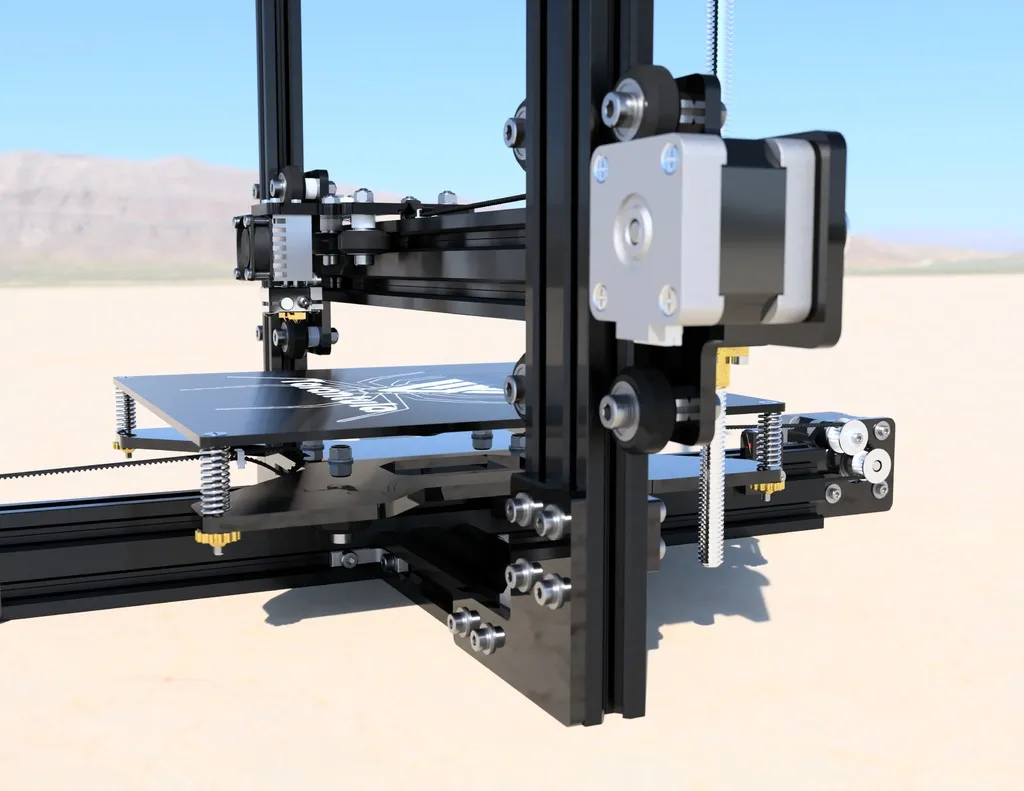

The design and build quality of the Tevo Tarantula models play a crucial role in their overall performance and user experience. These printers often feature a sturdy frame, usually constructed from aluminum extrusions, providing stability during the printing process. This robust frame minimizes vibrations and ensures precise movements, contributing to the quality of the prints. Furthermore, the open-frame design allows for easy access to the printer’s components, simplifying maintenance and upgrades. The overall build quality, while budget-oriented, is often considered good for its price point, making it an excellent starting point for those entering the 3D printing world. The design is often modular, making it easy to upgrade and customize the printer to suit individual needs and preferences. This modularity enhances its appeal to enthusiasts who enjoy modifying and improving their machines.

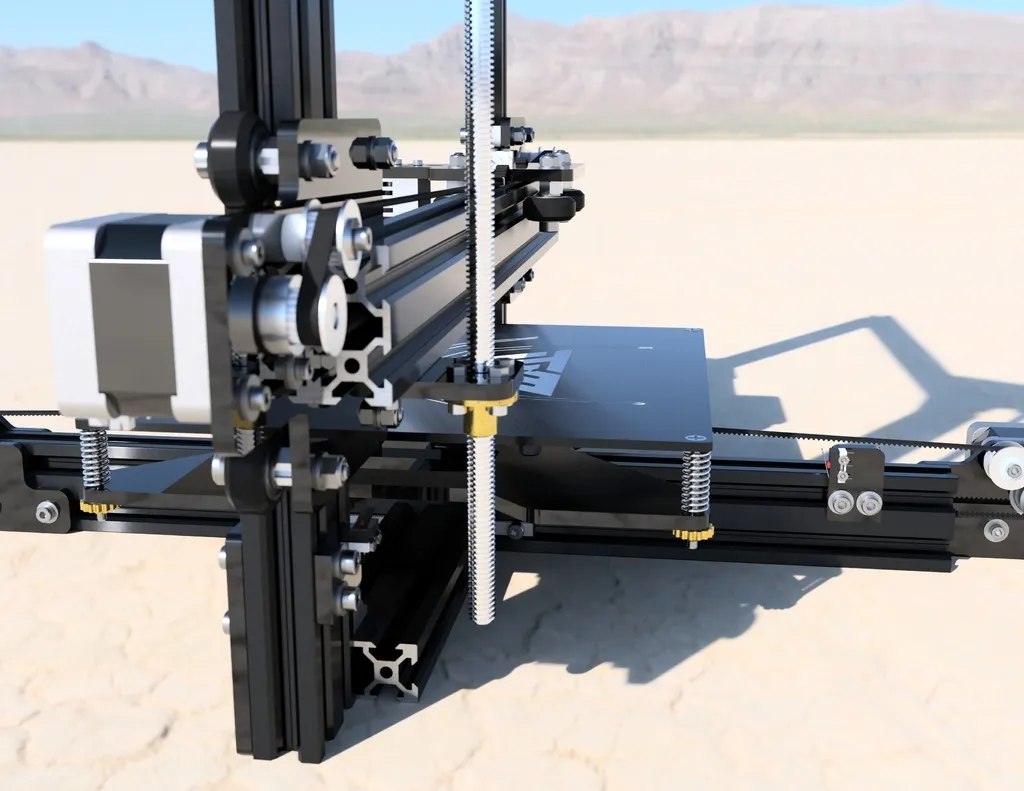

Frame Construction

The frame construction is a critical element of the Tevo Tarantula’s design, contributing significantly to the printer’s stability and print quality. The use of aluminum extrusions is a common feature. This material offers a good balance of strength and lightweight properties, essential for ensuring the printer can withstand the stresses of operation. A well-constructed frame minimizes vibrations, which can cause print imperfections. The rigidity of the frame is critical for maintaining dimensional accuracy in printed objects. It prevents the printer’s components from shifting during printing, which would lead to errors. The frame design typically allows for easy assembly and disassembly, which is beneficial for users who want to customize or upgrade their printers. The design often incorporates pre-drilled holes and slots, simplifying the process of attaching various components. The frame construction directly impacts the longevity and reliability of the printer, making it a vital factor for anyone considering purchasing a Tevo Tarantula model.

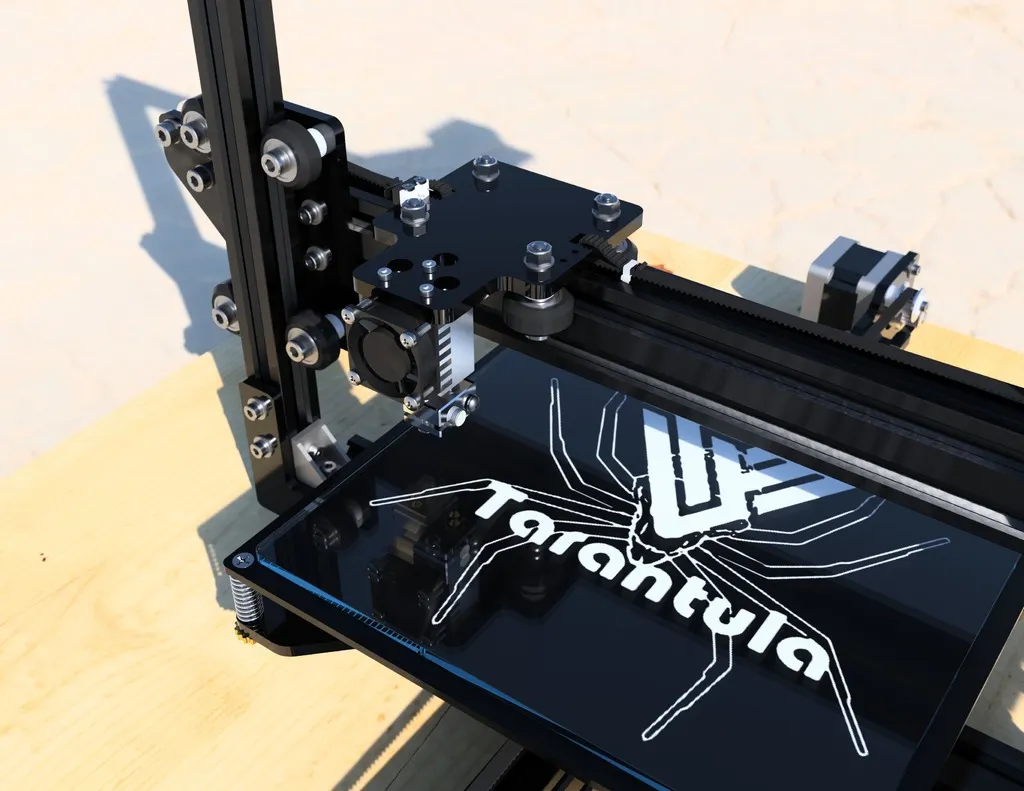

Print Bed

The print bed is a crucial component of any 3D printer. It is the surface where the printed objects are built layer by layer. Tevo Tarantula models typically feature heated print beds, allowing for the printing of a wider range of materials, including ABS, which requires a heated environment to prevent warping. The print bed’s size determines the maximum dimensions of the objects that can be printed. The bed should be flat and level to ensure that the first layer of the print adheres correctly. Proper bed leveling is vital for print success. It ensures that the nozzle is the correct distance from the print surface. Some Tevo Tarantula models incorporate features like auto-bed leveling, which simplifies the calibration process. This feature automatically adjusts the bed height to compensate for any unevenness. The print bed’s surface material also impacts print quality. Common options include glass, BuildTak, or PEI sheets, each offering different adhesion properties. Choosing the correct surface is important for achieving successful prints with various filament types. The print bed, therefore, is a vital part of the overall printing experience, playing a vital role in both print quality and the types of materials that can be used.

Extruder System

The extruder system is the heart of the 3D printing process. It melts the filament and deposits it onto the print bed. Tevo Tarantula models often utilize a Bowden extruder system, where the extruder motor is mounted on the frame, and the filament is fed through a tube to the hot end. This design reduces the weight on the print head, allowing for faster print speeds. The quality of the hot end is essential for melting the filament efficiently. A well-designed hot end ensures consistent filament flow. This, in turn, contributes to print quality. Some models may feature all-metal hot ends, which can withstand higher temperatures, enabling the use of a broader range of materials. The extruder system also includes a nozzle, which determines the print resolution and the level of detail. Different nozzle sizes are available, allowing users to optimize print speed or quality. Regular maintenance of the extruder system, such as cleaning the nozzle and checking the filament feed, is necessary for optimal performance and to prevent clogs. The extruder’s reliability and performance directly influence the printing experience and the quality of the final product.

Print Quality

Print quality is a primary concern for any 3D printer user. Tevo Tarantula models, when properly calibrated and maintained, can produce prints with good detail and accuracy. The print quality is influenced by several factors, including the printer’s mechanical components, the quality of the filament, and the settings used in the slicing software. Frame stability is essential for minimizing vibrations that can cause print defects. A well-constructed frame contributes to overall print quality. The quality of the hot end and the extruder also affects the outcome. They influence how precisely the filament is melted and deposited onto the print bed. Accurate bed leveling ensures that the first layer adheres correctly. This is a foundation for the entire print. Slicing software settings play a crucial role in print quality. Adjusting settings like layer height, print speed, and temperature can significantly impact the final result. The use of high-quality filament also contributes to better print quality. The filament’s consistency and properties influence the final print’s appearance and strength. With careful calibration and the right settings, Tevo Tarantula models can achieve impressive print quality, making them suitable for a variety of projects.

Ease of Use

Ease of use is a key factor that makes Tevo Tarantula models popular among beginners. The printers are generally designed to be relatively straightforward to assemble. They often come with clear instructions and a supportive community that offers guidance and assistance. The user-friendly nature of the machines makes them accessible to those new to 3D printing. Many models include features designed to simplify the printing process. These include auto-leveling capabilities, which reduce the need for manual bed leveling. The ease of use extends to the software side. The printers are typically compatible with popular slicing software, such as Cura and Simplify3D, which offer intuitive interfaces and pre-configured profiles for various filaments and printing settings. Furthermore, the online communities and forums dedicated to the Tevo Tarantula offer extensive support and troubleshooting resources. The availability of these resources ensures that users can quickly find answers to their questions and resolve any issues they may encounter. The ease of use is a significant advantage, enabling users to get started with 3D printing without a steep learning curve and contributing to a more enjoyable experience.

Assembly Process

The assembly process is a crucial aspect of the user experience. Tevo Tarantula models generally offer a moderate level of assembly complexity. However, this can vary slightly depending on the specific model. Most models come as kits, and users are required to assemble the printer from its component parts. The assembly process usually involves attaching the frame components, installing the motors and belts, and connecting the electronics. Clear instructions and diagrams are typically provided to guide users through the process. However, some experience with tools and mechanical components may be beneficial. Online resources, such as videos and community forums, often provide additional guidance and troubleshooting tips. The assembly time can vary, but it generally takes several hours for a first-time user to complete the process. Proper assembly is essential for the printer’s performance and print quality. Following the instructions carefully and ensuring all components are correctly aligned and tightened will help prevent issues down the line. The assembly process is a rewarding experience for many users. It allows them to learn about the printer’s inner workings and gain a deeper understanding of the technology.

Software Compatibility

Software compatibility is a key factor in the overall user experience. Tevo Tarantula models are generally compatible with a variety of 3D printing software, which makes the process accessible for users of all levels. Compatibility is important because the software is used to prepare the 3D models for printing. It involves slicing the models into layers and generating the G-code that the printer understands. The most common software used with Tevo Tarantula models is Cura, which is a free and open-source slicer known for its user-friendly interface and extensive features. Simplify3D is another popular option, though it is a paid software known for its advanced features and high-quality print results. The printers can also work with other slicing software like PrusaSlicer, which provides excellent print quality and supports a wide range of printers. The software compatibility ensures that users can select the slicer that best suits their needs and preferences. Some software packages offer pre-configured profiles for Tevo Tarantula models, simplifying the setup process. The printers’ ability to integrate with different types of software makes them versatile and adaptable to various printing projects and applications.

Slicing Software

Slicing software is the bridge between the 3D model and the physical print. The software is responsible for converting the 3D model into instructions that the printer can understand. Tevo Tarantula models are compatible with a range of slicing software options, but some choices are particularly popular. Cura is widely used due to its user-friendly interface and open-source nature. It allows users to adjust various settings like layer height, print speed, and temperature. Simplify3D is a more advanced, paid slicing software. It offers sophisticated features and produces excellent print quality. PrusaSlicer is another strong option. It provides a great balance of features and ease of use. The slicing software allows users to import 3D models, adjust their size and orientation, and add supports as needed. They also allow users to control many printing parameters, such as infill density and wall thickness. The choice of slicing software can significantly impact the print quality. A good slicer can optimize the print settings to minimize errors and maximize print accuracy. Learning to use a slicer effectively is an essential skill for any 3D printing enthusiast.

Firmware

Firmware is the software that controls the printer’s hardware, including the motors, heating elements, and sensors. Tevo Tarantula models usually run on open-source firmware like Marlin. This firmware allows users to customize and update the printer’s functionality. The firmware is responsible for interpreting the G-code generated by the slicing software and controlling the printer’s movements. Updates to the firmware can improve print quality and add new features. The firmware also manages the printer’s temperature control and ensures that the heating bed and hot end reach the correct temperatures. The firmware’s ability to be modified and updated is an advantage for users. It allows them to adapt their printers to different filaments and printing requirements. Furthermore, the open-source nature of the firmware enables a community to provide support and develop new features. The firmware plays a vital role in the printer’s performance and overall user experience. It determines how efficiently and accurately the printer operates. Regularly updating the firmware ensures the printer is running optimally and has the latest features.

Printing Materials

The ability to print with a variety of materials is a significant advantage of Tevo Tarantula models. The printer is compatible with different filament types, each offering its unique properties and applications. The choice of material depends on the intended use of the printed object. Common materials include PLA, ABS, PETG, and TPU. Each material has different properties regarding strength, flexibility, and temperature resistance. Proper temperature settings are important for optimal results. Using the correct settings helps the filament to melt and adhere to the print bed. The printing temperature settings vary depending on the material being used. The selection of materials depends on the desired characteristics of the final product. For example, PLA is good for prototypes, while ABS is suitable for more durable parts. PETG is known for its balance of strength and flexibility. TPU is a flexible material ideal for creating rubber-like objects. The ability to use a wide range of materials makes the Tevo Tarantula a versatile tool for various projects.

Filament Types

The choice of filament type is a critical factor in 3D printing. Tevo Tarantula models can handle a wide array of filaments. These filament types have distinct properties that suit different applications. The most common filaments are PLA, ABS, and PETG. PLA is easy to print with and is environmentally friendly. It is suitable for beginners and for printing prototypes and decorative items. ABS is known for its durability and temperature resistance. It is ideal for functional parts, although it requires a heated bed to prevent warping. PETG combines the strengths of PLA and ABS. It offers good strength and flexibility, making it versatile. The filament selection depends on the specific requirements of the print. The properties like strength, flexibility, and temperature resistance need to be considered. Different filaments need different printing settings. This includes the temperature of the hot end and the print bed. The quality of the filament also influences the print quality. Using high-quality filament leads to better results. Understanding the properties of different filament types allows users to choose the best material for their projects.

PLA

PLA (Polylactic Acid) is a popular filament choice for 3D printing with Tevo Tarantula models. This filament is easy to print with and is made from renewable resources like cornstarch. PLA is known for its low printing temperature and minimal warping, making it ideal for beginners. It is biodegradable and emits fewer fumes than some other filaments. PLA is available in a wide range of colors and is suitable for printing decorative objects and prototypes. Its low printing temperature does not require a heated bed. However, it can be used to improve adhesion. The ease of use and eco-friendliness make PLA a good option for hobbyists and educational purposes. PLA is a good choice for parts that don’t need to withstand high temperatures or mechanical stress. PLA is less durable than ABS or PETG. PLA has a lower glass transition temperature, which means it can soften or deform in high-temperature environments. For many users, PLA is the first choice for printing because of its ease of use and wide availability.

ABS

ABS (Acrylonitrile Butadiene Styrene) is another widely used filament type compatible with Tevo Tarantula models. ABS is known for its durability and temperature resistance. It is a good choice for functional parts that need to withstand stress or exposure to heat. ABS requires a higher printing temperature and a heated bed to prevent warping. Printing ABS requires proper ventilation, as it can emit fumes during the printing process. The higher printing temperature allows for stronger layer adhesion. ABS prints can be sanded, painted, and glued for further customization. ABS is more resistant to impact and wear than PLA. ABS is not biodegradable and can release fumes, so it’s important to print in a well-ventilated area. ABS is commonly used to create mechanical parts, enclosures, and other functional objects. ABS has a high glass transition temperature, so it can withstand exposure to higher temperatures without deforming. The strong and durable nature of ABS makes it popular for printing parts that are used in a more practical setting.

Advanced Features

Tevo Tarantula models often include advanced features that enhance their capabilities and user experience. These features can vary depending on the specific model. Some common advanced features include heated beds, auto-leveling, and connectivity options. Heated beds are essential for printing with materials like ABS, which require a warm printing environment to prevent warping. Auto-leveling simplifies the calibration process. It automatically adjusts the print bed height. Connectivity options include USB, SD card, and sometimes Wi-Fi. They enable users to transfer print files and monitor the printer remotely. Other advanced features may include dual extrusion. The dual extrusion enables the printing of multi-color objects or objects with support structures. The inclusion of advanced features increases the versatility and convenience of the Tevo Tarantula models. The combination of features makes them more suitable for different printing needs. These features also make them more appealing to experienced users who want to explore the capabilities of their printers.

Heated Bed

The heated bed is one of the most important advanced features. The heated bed is a component that warms the print bed to a specific temperature. This feature is especially critical when printing with ABS, which is prone to warping. The heated bed helps the first layer adhere to the print bed correctly. It minimizes the chances of the print curling or detaching during the process. The heated bed also enables the use of a wider range of materials. Some materials, such as PETG, benefit from a heated bed. The heated bed enhances the print quality by ensuring proper layer adhesion. It also improves the overall print success rate. The temperature of the heated bed can be adjusted in the printer’s firmware or the slicing software. The correct temperature depends on the filament being used. Properly managing the heated bed’s temperature is important for consistent printing results. The heated bed is a key component that helps make the printing process more reliable and efficient.

Auto-Leveling

Auto-leveling is a feature designed to simplify the calibration process. It automatically measures the distance between the nozzle and the print bed at various points. The printer then uses this data to compensate for any imperfections in the bed’s surface. This feature eliminates the need for manual leveling. It involves adjusting the bed height using screws or other mechanisms. Auto-leveling helps to ensure that the first layer of the print adheres correctly. It contributes to the overall success of the print. Auto-leveling typically uses a sensor to detect the distance between the nozzle and the bed. The sensor can be inductive, capacitive, or even a physical probe. The data collected is then used to create a virtual bed level map. This map is then used to adjust the nozzle height during printing. Auto-leveling improves print quality and reduces the risk of errors caused by an uneven bed. Auto-leveling is a valuable feature for both beginners and experienced users. It can save time and improve the overall printing experience.

Connectivity

Connectivity options are important for ease of use and the convenience of Tevo Tarantula models. Common connectivity options include USB, SD card, and Wi-Fi. USB connections allow users to connect the printer directly to a computer and transfer print files. The SD card provides a way to store print files and print them without a computer connection. Some models include Wi-Fi connectivity. This enables users to send print files wirelessly and monitor the printer remotely. The connectivity options depend on the specific model of Tevo Tarantula. Each type of connectivity has its advantages. USB is a straightforward option for direct printing. SD cards provide portability and can be used without a computer. Wi-Fi enables remote monitoring and control. The choice of connectivity depends on the user’s preferences. Connectivity enhances the overall printing experience by making it easier to manage and control the printing process. With connectivity options, users can monitor their prints from anywhere. These features offer more flexibility and convenience in 3D printing.

Conclusion

Tevo Tarantula models offer a compelling combination of features, making them a popular choice in the 3D printing community. From their sturdy design and user-friendly interface to their advanced features and the ability to use a wide variety of materials, these printers provide an excellent balance of affordability, performance, and accessibility. The ease of use and robust online support make them especially attractive to beginners. The Tevo Tarantula’s modular design also allows for modifications and upgrades. This is a great feature for experienced users. Whether you are a hobbyist, a student, or a professional, the Tevo Tarantula can offer a rewarding 3D printing experience. Its strengths make it a reliable and versatile option in the ever-growing world of 3D printing.