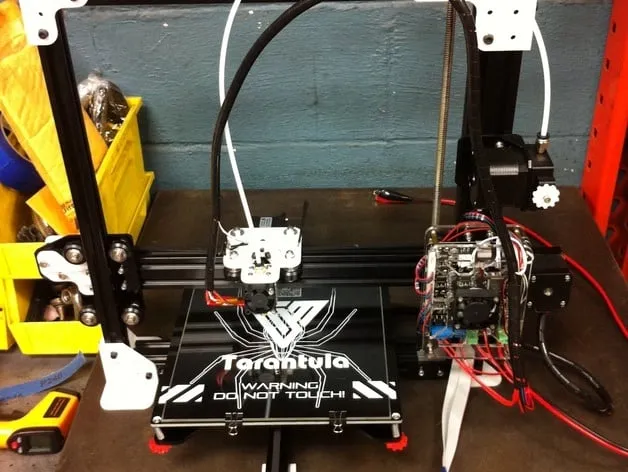

Understanding the Dual Y Rail Upgrade for Tevo Tarantula

The Tevo Tarantula has gained popularity among 3D printing enthusiasts, known for its affordability and ease of modification. One of the most impactful upgrades you can perform on this printer is installing a dual Y rail system. This enhancement dramatically improves print quality, stability, and overall performance. This guide explores everything you need to know about upgrading your Tevo Tarantula with a dual Y rail, from the basics to detailed installation and maintenance tips. By understanding the advantages of this upgrade, you’ll be well-equipped to take your 3D printing to the next level.

What is a Dual Y Rail System?

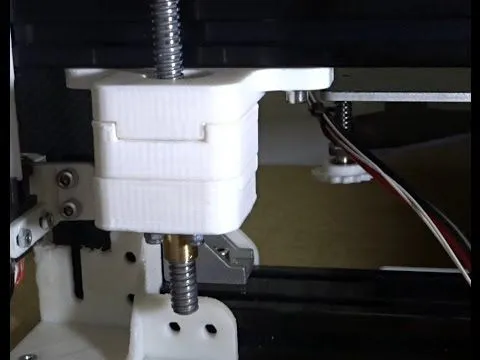

A dual Y rail system replaces the standard single Y-axis rail of the Tevo Tarantula with two parallel rails. These rails run along the Y-axis, which is the direction the print bed moves back and forth. This configuration provides significantly more support and stability to the print bed, reducing wobble and improving the precision of your prints. The dual rail system often involves replacing the existing single rail with two high-quality linear rails, ensuring smooth and accurate movement along the Y-axis. This system is a foundational upgrade, enhancing the printer’s mechanical integrity and print capabilities.

Benefits of Upgrading to a Dual Y Rail

Upgrading to a dual Y rail system on your Tevo Tarantula provides several key benefits that enhance your 3D printing experience. These improvements affect both the quality of your prints and the reliability of your printer’s operation. By understanding the advantages, you can make an informed decision about whether this upgrade is right for your needs. The key advantages include enhanced stability, improved print quality, and increased printing speed.

Enhanced Stability

The primary advantage of a dual Y rail system is enhanced stability. The dual rails distribute the weight of the print bed more evenly, minimizing vibrations and wobbling during printing. This is particularly crucial during high-speed prints or when printing larger objects. The increased stability results in a more consistent and reliable printing process, reducing the chances of failed prints due to bed movement.

Improved Print Quality

With the added stability, you’ll notice a significant improvement in print quality. Reduced vibrations translate to cleaner lines, sharper details, and overall better surface finishes. The dual Y rail system allows for more precise layer adhesion, resulting in stronger and more visually appealing prints. This improvement is particularly noticeable in complex geometries, where even slight movements can cause print imperfections.

Increased Printing Speed

By reducing wobble and improving stability, the dual Y rail system allows you to print at higher speeds without sacrificing print quality. The print bed can move more rapidly and smoothly, enabling faster print times. This is particularly advantageous for users who need to produce prints quickly or who are involved in rapid prototyping. However, it is always important to calibrate the printer and find the optimal speed settings for both quality and speed.

Top 5 Dual Y Rail Upgrades for Your Tevo Tarantula

When choosing a dual Y rail system for your Tevo Tarantula, several key components contribute to its overall performance. Selecting high-quality components ensures the longevity and effectiveness of the upgrade. Here are the top 5 upgrades to consider when upgrading your printer.

High-Quality Linear Rails

The linear rails themselves are the foundation of the upgrade. Look for rails made from hardened steel or high-quality aluminum alloys, as they provide smooth and precise movement. Ensure the rails are compatible with the Tevo Tarantula’s frame size. High-quality rails minimize friction and wear, ensuring long-term reliability and consistent print quality. Choose rails that are designed for 3D printing, as they will offer better performance and durability.

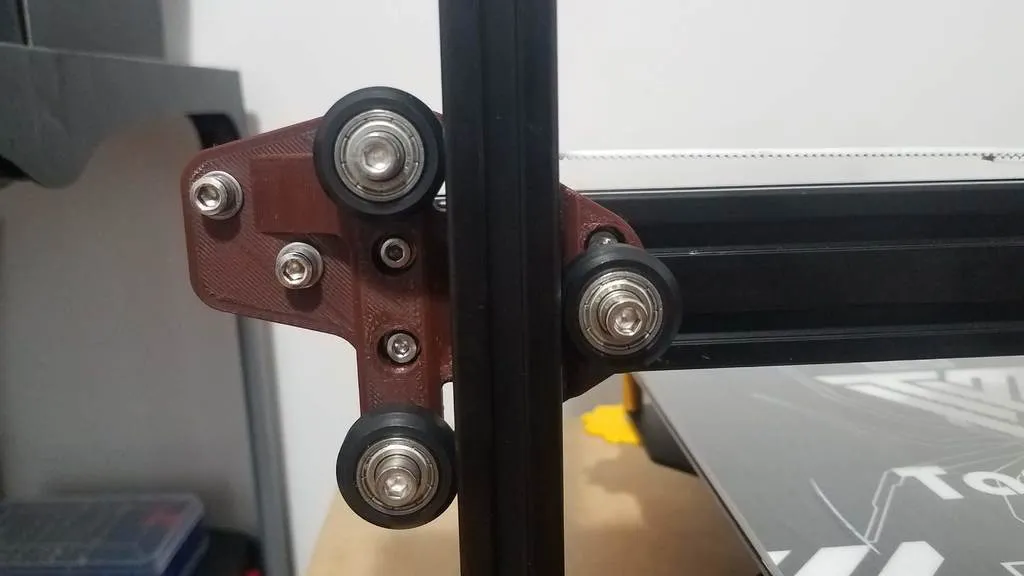

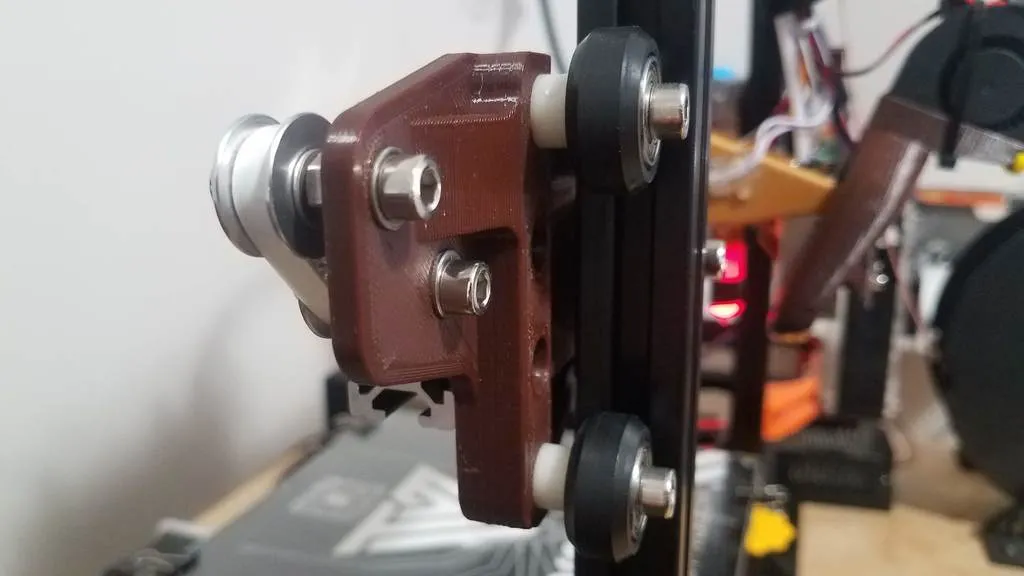

Sturdy Y-Axis Brackets

Sturdy brackets are essential for securely mounting the linear rails to the printer’s frame. They must be robust enough to withstand the forces generated during printing and prevent any movement or flex. Consider brackets made from aluminum or other rigid materials. These brackets should also be designed to align the rails precisely, ensuring optimal performance. Proper alignment is crucial for preventing binding and ensuring smooth movement of the print bed.

Precise Belt Tensioners

Belt tensioners are critical for maintaining the correct tension in the Y-axis belts. Correct belt tension is crucial for accurate movement and minimizing backlash. Look for adjustable tensioners that are easy to use and provide fine control over the belt tension. Belt tensioners will also prevent problems like ghosting or ringing in your prints. Precise tensioning ensures that the print bed moves in sync with the stepper motors.

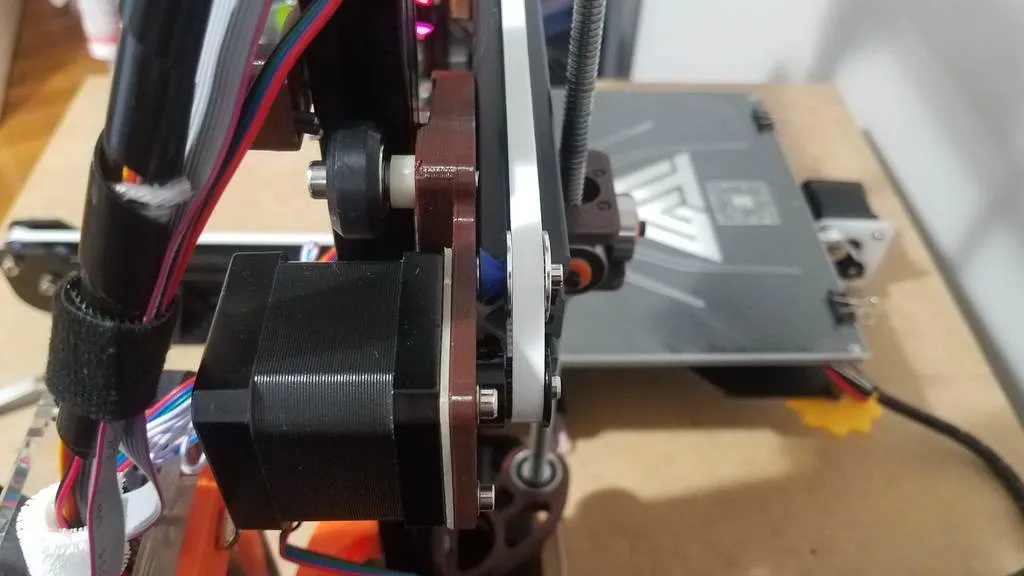

Upgraded Stepper Motors

While not always required, upgrading your stepper motors can further enhance performance, especially when printing at higher speeds. More powerful motors can provide more torque, allowing for faster and more precise movements of the print bed. Be sure your power supply can handle any new load. Upgrading the motor, in conjunction with the other upgrades mentioned, makes the Tevo Tarantula even more robust and efficient.

Reinforced Frame

To fully benefit from a dual Y rail system, consider reinforcing the printer frame. This reduces flex and ensures that the entire structure remains stable, especially during high-speed printing. Reinforcement can involve adding extra supports or braces to the frame. A more rigid frame prevents any unwanted movement or vibration, allowing the dual Y rail system to perform at its best.

Installation and Setup

Installing a dual Y rail system on your Tevo Tarantula requires careful planning and execution. The process involves several steps, from preparing the printer to calibrating and testing the upgraded system. Following these steps carefully will ensure a successful installation and optimal performance. Following instructions and double checking the work will guarantee good results.

Preparing Your Tevo Tarantula for the Upgrade

Before starting the installation, it’s essential to prepare your Tevo Tarantula. First, disconnect the power and remove any existing components from the Y-axis, including the print bed, belt, and any associated hardware. Clean the frame to ensure a clean surface for the new components. Ensure all necessary tools are on hand. Organize the workspace so you can maintain order and minimize the risk of losing parts during the upgrade process.

Installing the Dual Y Rail System

Carefully mount the linear rails to the printer frame using the provided brackets and hardware. Ensure the rails are aligned correctly to minimize binding. Then, install the Y-axis brackets, attaching them securely to both the rails and the print bed. Next, install the belt tensioners. Finally, connect the Y-axis belt and make sure it’s under the correct tension. Refer to the instructions provided with your dual Y rail kit, and take your time to ensure everything is assembled correctly.

Calibrating and Testing the Printer

After installation, calibrate the printer to ensure the dual Y rail system functions correctly. Adjust the bed level and ensure smooth movement along the Y-axis. Test the system by performing a few test prints. Use test prints to check for any issues with movement, layer adhesion, or overall print quality. Make any necessary adjustments to the belt tension, bed leveling, or other settings. Perform this step meticulously to ensure optimum performance from the dual Y rail system.

Maintaining Your Dual Y Rail System

Proper maintenance is critical for ensuring the longevity and optimal performance of your dual Y rail system. Regular maintenance will help prevent wear and tear, ensuring the smooth and accurate movement of your print bed. By following these maintenance tips, you can keep your printer running smoothly for years to come.

Regular Lubrication

Lubricate the linear rails regularly with a suitable lubricant, such as lithium grease or a specialized linear rail lubricant. Lubrication reduces friction and wear, ensuring smooth movement. Apply a small amount of lubricant to the rails and move the print bed back and forth to distribute it evenly. Lubricate the rails every few printing sessions or as needed, depending on usage.

Checking Belt Tension

Periodically check the tension of the Y-axis belts. Belts that are too loose can cause print inaccuracies and ghosting. Belts that are too tight can strain the stepper motors. Use the belt tensioners to adjust the tension as needed, aiming for the optimal balance between precision and motor performance. Check the belt tension regularly, especially after extended periods of printing or after any maintenance.

Inspecting for Wear and Tear

Inspect the linear rails, brackets, and belts for any signs of wear and tear. Look for any damage, such as scratches, dents, or cracks. Check the belt for fraying or stretching. Address any issues promptly to prevent further damage and maintain print quality. Replace any worn components immediately to maintain your printer’s performance.

In conclusion, upgrading your Tevo Tarantula with a dual Y rail system is a worthwhile investment for 3D printing enthusiasts. The enhancements in stability, print quality, and speed make it a transformative modification. By following the steps outlined in this guide, you can successfully install and maintain this essential upgrade. Embrace the possibilities of improved 3D printing with a dual Y rail system on your Tevo Tarantula, unlocking new levels of precision and efficiency in your projects.